From the outdoors it appears like a common company building, great deals of glass as well as steel, however this manufacturing facility in the south of the Netherlands comes from ASML, and also the devices made there are anything but common.

As a matter of fact, the modern technology is so sophisticated therefore much popular, that ASML has actually come to be Europe’s most valuable modern technology company.

So what is made there?

ASML layouts and also makes the makers which make computer chips – yet not any old integrated circuit.

ASML machines make the most advanced computer chips as well as it’s the only company worldwide with that said sort of innovation.

This effective syndicate means that precisely just how ASML’s equipments work undergoes several of the most stringent business security on the planet.

Nonetheless, we were given a scenic tour of its plant, as well as were assisted through the fundamentals.

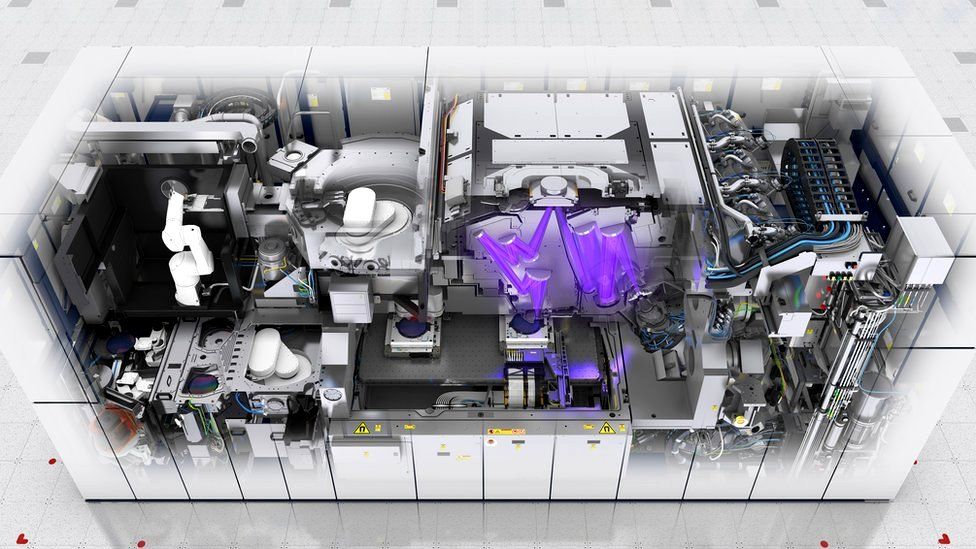

Integrated circuits are made by developing complex patterns of transistors, or mini electric switches, layer by layer, on a silicon wafer.

They are printed making use of a lithography system, where light is predicted via a blueprint of the pattern of those small switches.

The light is after that diminished and focussed utilizing advanced optics and also the pattern is engraved onto a photosensitive silicon wafer.

That pattern develops the circuitry of a silicon chip, that might end up in a computer, phone or any various other electrical device you may care to discuss.

The essential facet of ASML’s most sophisticated devices is that they can operate at little ranges by producing super fine extreme ultraviolet light – just 13.5 nanometres.

Sander Hofman from ASML compares it to making use of pens with various suggestions: “Due to the small wavelength, that indicates that you generally are utilizing a fine lining to attract these lines of integrated circuitry – as opposed to older generation makers which use possibly a marker pen.”

The capacity to engrave the silicon with such great circuits means you can pack much more parts on to the silicon which, subsequently, indicates digital gadgets can have much more processing power and also more memory while continuing to be the same dimension.

The makers run in a vacuum, as the whole process of etching a chip, can be derailed by the smallest of impurities – like a rogue skin particle.

Technician, Bram Matthijssen was assembling among ASML’s most recent layouts when we checked out the manufacturing facility. Mr Matthijssen works in among the cleanest settings on the planet.

“There are moments where we have to wear gloves over gloves to make sure we don’t leave any type of finger prints, to make sure we do not bring any additional dust into the machine.

“A solitary finger print … can cause significant damages to the maker,” he claims.

The machines themselves are extremely substantial and also complicated. One extreme ultraviolet (EUV) device can take a year to set up and also provide.

In 2015 the company delivered only 50 of their highest possible specification model as well as 400 machines in total.

Those sales, plus revenue from the administration and also upgrading of existing makers, made the business 21.2 bn euros ($22.7 bn; ₤ 18.9 bn) in 2014.

The orders they have in the pipeline deserve double that. The sales development suggests an expanding labor force, up by a 3rd over the last one year.

Wayne Lam, an expert with innovation research company CCS Insights, says the devices ASML make take years, if not decades, to develop and also best.

ASML has been dealing with its highest possible requirements makers because the very early 2000’s, leaving various other business in the area with quite a bit of reaching do.

“I make certain there are rivals in the works … nevertheless, in the near term there isn’t any type of real rival to ASML,” he claims.

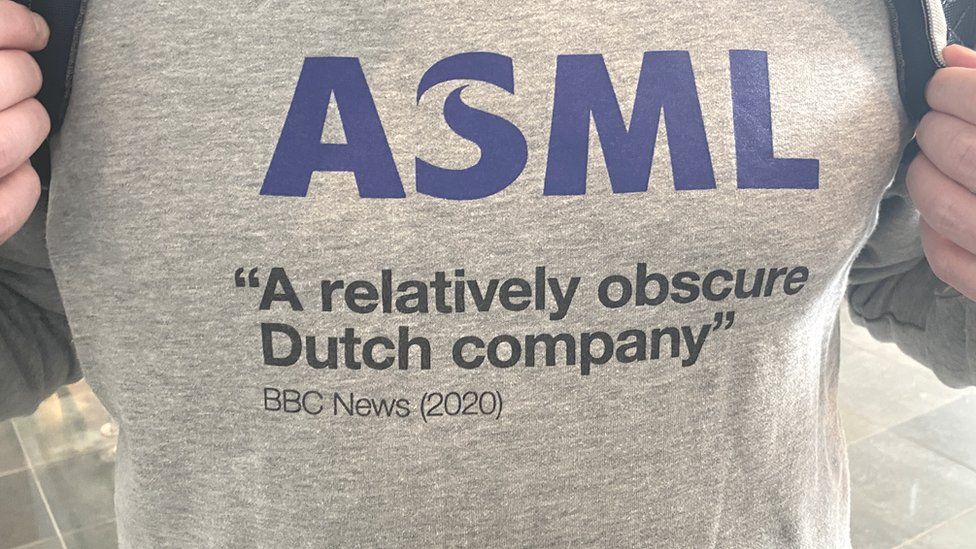

Okay for a business when defined by the BBC as “fairly rare”, a quote which Mr Hoffman has actually printed on a hoodie.

Being such a critical cog in the worldwide electronic devices market includes troubles.

ASML presently finds itself captured in the rivalry in between the United States as well as China.

China has long wanted to make the most sophisticated integrated circuit, for which it requires ASML machines.

But considering that 2019, the US has actually efficiently been blocking ASML from exporting those machines to China.

Joris Teer, a tactical analyst at The Hague Centre for Strategic Research states the US is keen to avoid China from catching up in chip technology.

“The US have actually relocated their goals, from having a number of generations of a benefit on their opponents, to we need to preserve as huge a lead as possible – which can likewise mean you have to place your rivals back as far as feasible,” he claims.

Last Updated: 21 February 2023